Client Cases

Here you will see specific cases where we have worked with our clients to make their project a reality.

Pinion:

Our customer needed this part for his assembly. Any other type of production was 5 times more expensive, yet there could be no compromise on the properties. Continuous Metal Technology’s engineering staff formulated an alloy and tooling for the project, which has saved them over $20.00 a part and 5 million dollars over the last 10 years.

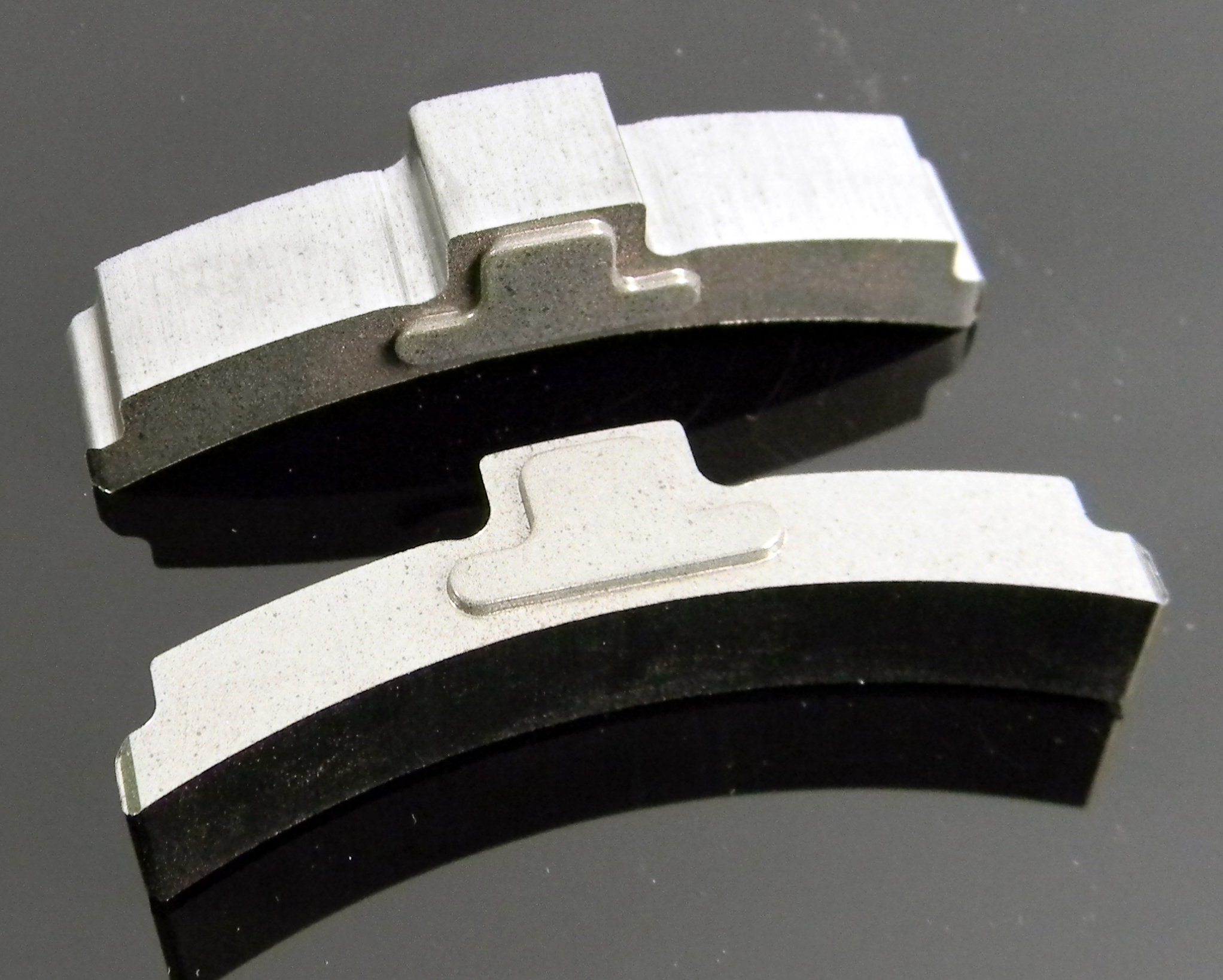

Clutch Wedge:

Our customer was machining this part when they came to us. They were looking for comparable properties and cost savings. Our engineering team was able to design the tooling and alloys to accomplish this, giving the customer a 65% cost savings per part and a yearly savings of $200,000.00.